Similarities and Differences Between Overhead Crane Types

Aug 18, 2022

Many businesses rely on overhead cranes for material handling operations both indoors and outdoors. For loads that are too heavy to move manually or items that must be stored out of reach of other equipment, an overhead crane system gives you the ability to lift tons of weight to a variety of places with ease.

There are numerous types of indoor cranes and outdoor cranes at your disposal, making it easy to get the exact right crane for your application. Here’s a complete guide to the pros and cons of different types of overhead cranes.

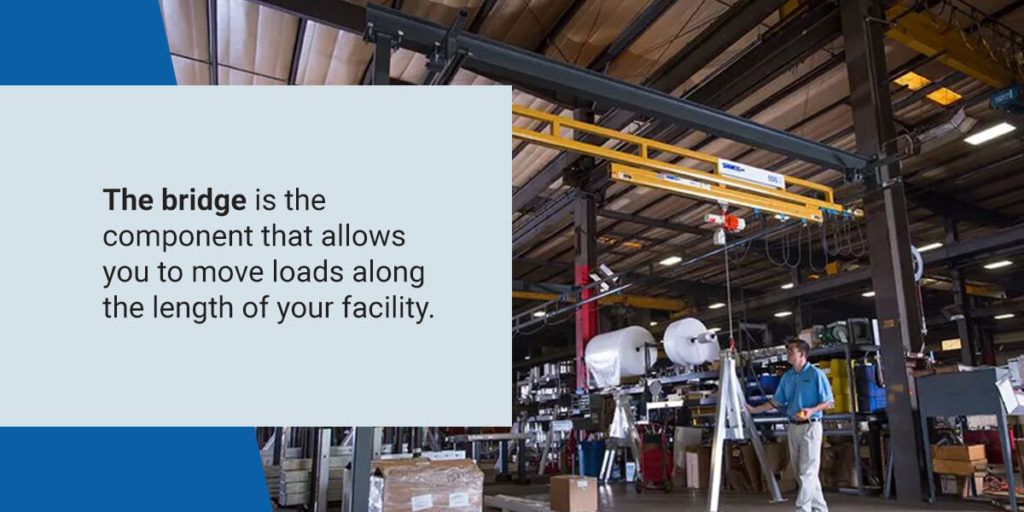

1. Bridge Crane

The overhead bridge crane is one of the most common types of cranes on the market. Two overhead runway beams support at least one bridge that travels the length of the system. The runways may be freestanding or supported by the building’s structure.

Bridge Crane Uses

Bridge cranes can be found in many industrial settings. Businesses often use bridge cranes in storage and warehousing applications, either to load and unload materials entering or exiting a facility or to move material to designated positions within a facility. Bridge cranes are also used frequently to move large parts or components for assembly in manufacturing applications.

Pros of Bridge Cranes

Bridge cranes are useful for a number of reasons:

- Customization: You can customize bridge cranes with hook attachments, special material handling tools and riggings. Many bridge cranes can also be expanded after installation.

- Efficiency: Because bridge cranes travel above obstructions, so they don’t waste time navigating through obstacles.

- Large coverage area: Bridge cranes provide precise, corner-to-corner coverage over a rectangular area. Bridge crane coverage can extend as far as you can install runways—even up to the full length of your facility.

Cons of Bridge Cranes

Bridge cranes offer many benefits, but they are not suitable for every situation.

- Limited capacity: Spanco Workstation Bridge Cranes are not available with capacities over 4,000 pounds, which means they are not usable for heavier lifting applications.

- Floor space: Some bridge cranes mount directly to a building’s existing support structure. However, if a building can’t support the weight of the crane and its load, multiple support columns are required, which can take up valuable floorspace.

2. Jib Crane

A jib crane is a type of crane that’s intended to save space. Jib cranes are best for jobs that require repetitive movement in a small area. They come in a variety of sizes, but all move in a circular motion with 180 to 360 degrees of rotation.

Jib Crane Uses

Jib cranes can be found at many different types of facilities, including factories, mines, assembly lines, docks, workshop production lines, and other situations that require frequent material handling. They’re best used for handing materials in individual workstations. You can customize your jib crane with hoists, balancers, and manipulators to ensure it fits your exact needs.

Spanco offers hundreds of pre-engineered jib crane with capacities ranging from 100 pounds to 15 tons. All models fold out of the way of overhead cranes to make your workflow smooth.

Pros of Jib Cranes

Jib cranes provide a number of benefits to your project and your worksite as a whole:

- Higher capacity: Spanco Jib Cranes offer capacities up to 15 tons.

- Small footprint: Jib cranes swivel around a single point, meaning they only occupy a small amount of floorspace.

Cons of Jib Cranes

Jib cranes also come with limitations:

- Smaller coverage area: Because jib cranes are supported only at a single point, a single system offers limited coverage. Even with an area 40 feet in diameter, a jib crane’s coverage is less than that of a bridge or gantry crane.

- Limited use: Jib cranes’ smaller coverage area means each jib crane is typically limited to use in just one or two workstations.

3. Gantry Cranes

Gantry cranes support a trolley a hoist on legs that travel on the ground. The design is comparable to a self-supporting bridge crane.

Gantry cranes come in a variety of models, offering you flexibility to find the best solution for your needs. Many Spanco Gantry Cranes also offer adjustable height, span, and tread, so they can be used for different jobs as needed.

Gantry Crane Uses

Gantry cranes can be used in many different industrial settings. You’ll often find them in shipyards, construction sites, rail yards, steel mills, factories, and anywhere else materials have to be moved from one place to another.

Pros of Gantry Cranes

Gantry cranes provide unique flexibility in your facility, combining many of the benefits of bridge cranes and jib cranes.

- Higher capacity: Spanco Gantry Cranes, like Spanco Jib Cranes, offer a maximum capacity of 15 tons.

- Flexible coverage area: Gantry cranes can cover a small area, such as a single workstation, or the entire length of a facility, depending on your needs.

- Portable: Gantry cranes can be moved to provide material handling coverage anywhere you need it.

- Adjustable: Because many Spanco Gantry Cranes offer adjustable height, a single gantry crane can be used for multiple different tasks and processes.

- Movement under load: All Spanco Gantry Cranes can be moved under load, providing virtually the same operating capabilities as a bridge crane without the fixed structure.

Cons of Gantry Cranes

Although they combine the benefits of other types of cranes, gantry cranes aren’t perfect for every situation.

- Floorspace: Gantry cranes travel along the floor of your facility, which means the ground in a crane’s operating area must remain clear and free of obstructions.

4. Monorail Cranes

Monorail cranes carry a load along a single path designated by a rail. The trolley of a monorail crane runs along a track that’s usually secured to a building’s ceiling or other support structure. If a ceiling is unusable, monorail cranes can be supported on a freestanding support structure.

Monorail Crane Uses

Monorail cranes are best for lifting applications that require regular movement along a fixed path. The rails on a monorail crane can be designed to fit your unique specifications by adding switches, branches, changes in elevation, and curves.

Pros of Monorail Cranes

- Cost: Monorail cranes are a simple design, making them a low-cost, economical option.

- Straightforward: Applications that don’t require a high degree of flexibility can employ a monorail crane easily and efficiently.

Cons of Monorail Cranes

- Lack of flexibility: The monorail crane’s strength is also one of its biggest drawbacks. Because monorail cranes do not offer much flexibility, they are typically limited to a few specific applications.

Which Crane Is Right for You?

Choosing the right crane for your facility requires you to think through several factors that are unique to your situation. Whether you’re looking for outdoor or indoor cranes, you’re sure to find the best fit for you.

Cranes aren’t one-size-fits-all, so you must choose the one that makes your workflow the smoothest. Hopefully, these lists of pros and cons will help you decide. If you’re still not sure, check out this blog on how to choose an overhead crane.

Our system selector tool also gives you the ability to see the different types of cranes you have for an overhead crane based on several criteria. Based on your inputs, you’ll see the system or systems that best fit your specific needs. You can then inquire about the crane you’re matched with and move forward with the process.

Reach Out to Spanco to Learn More

For more than four decades, Spanco has been providing industries with high-quality, cost-effective material handling solutions. As our business has grown, we’ve developed the resources, experience, and knowledge to meet your needs and provide you with the best customer service we possibly can.

With our bi-coastal manufacturing facilities, you can rest assured that we have the capacity to deliver your equipment no matter where your facility is located. Further, after a fall event, you don’t have to recertify or replace any of the parts in our cranes — our systems only necessitate a completed visual inspection. As a result, you can get back to work faster.

Contact us today to learn more or begin the process of finding the right overhead crane for your facility. If you’re seeking a representative, you can find one in your area here. We promise that the product you purchase from us will be durable and perform the job exactly as intended.

Categories

Share this post

Contact us

Looking for the perfect fall protection equipment? Let us help!