Posts by developer

Maintain A Constant Flow of Materials with the Right Lift Equipment

It’s no secret that manufacturing facilities need to maintain a constant flow of working materials. Every manufacturing company wants to streamline their manufacturing process, from incoming raw materials to fabrication, packaging, and shipping. Interruption in the manufacturing process will inevitably decrease production. But, the right lift equipment can help maintain your workflow and streamline your…

Read MoreOverhead Crane Inspection Classifications

¿ Overhead cranes are important for moving equipment and materials in many industries. Operating and maintaining overhead cranes correctly contributes to safer working environments for employees while reducing downtime and costly incidents. There are also various regulations you must follow, and consistent inspections are one of the main parts of compliance. The Occupational Safety and…

Read MoreCommon Misconceptions in Crane Safety

With so many myths in the workforce about overload, side pull, limit switches, and even daily inspections, we wanted to address these issues and clarify any misconceptions. According to The Fabricator Online, “being aware of common misconceptions will save your equipment and even may save your life.” Overload Too often, workers and crane operators believe…

Read MoreAsk Spanco: What’s the Difference Between a Dedicated and Non-Dedicated Crane Operator

We receive a lot of questions about dedicated and non-dedicated crane operators and how their roles and safety concerns differ. While there is not a lot of information online about the topic, the CMAA does provide insight in their Crane Operators Manual (Specification 79-2012), as outlined below. Workstation bridge cranes, gantry cranes, and jib cranes…

Read MoreOverhead Cranes for Marine-Duty Locations

For most marine-duty applications, the overhead crane must be equipped to withstand harsh marine conditions in a corrosive salt-water environment. This application calls for specific types of overhead lift systems that are specifically designed for marine and outdoor applications. If you’re looking for a crane you can use within five miles of salt-water, we do…

Read MoreSafeguarding Your Production Process

According to an online article by The Fabricator, “The best way to make sure that machine operators can do their jobs effectively with proper safeguarding is to design machine systems around those safety devices in the first place.” (1) One way to easily avoid this problem is to integrate safeguards during the early design stages…

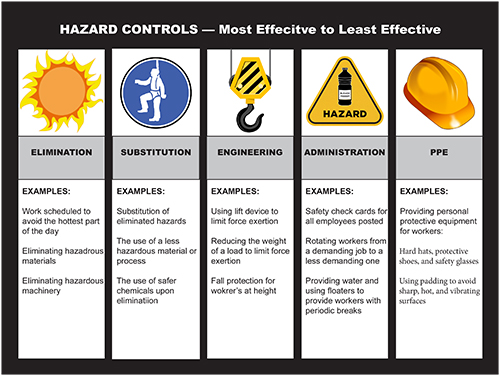

Read MoreHierarchy of Hazard Control

Ergonomic solutions in manufacturing facilities have advanced significantly in recent times. A common reason why companies introduce these solutions is to improve efficiency and productivity. However, many companies are also integrating ergonomic hazard control strategies to reduce workplace injuries. According to the International Labour Organization, the manufacturing sector is one of the most hazardous, contributing…

Read MorePneumatic Vs. Polyurethane—Let’s Talk Casters

If you’ve been searching for the right gantry crane, lift truck, or rolling lift system for your specific application, there are several options to consider. It’s important to ask yourself questions like: do I need a light-weight system that can be moved from one location to another quickly and easily, or does my application require…

Read MoreControl Technology for Overhead Cranes

Engineers and crane manufacturers have significantly improved overhead cranes—structurally and mechanically—over multiple decades. While these improvements have made material handling easier, more productive, and ergonomic, it’s the control technology that has truly revolutionized safety and ease of use. Control systems are an essential part of an overhead crane or hoist because they allow the crane…

Read MoreProper Inspection of Overhead Cranes

Proper inspection of overhead cranes is important because it helps ensure safe equipment operation. Thoroughly inspecting overhead cranes improves operator safety and prevents operator injury. Proper inspection has many advantages: Reducing time lost caused by equipment breakdown Detecting potentially hazardous conditions Reducing the costs of repairs by correcting defects before equipment is seriously damaged Uncovering…

Read MoreSafe Use of Lift Equipment: Assessing Risk and Reinforcing Pre-Start Checks

Overhead cranes and other lifting accessories are an essential part of manufacturing and construction for a lot of companies. Cranes improve business operations from a production standpoint and provide an efficient method of material handling that can help eliminate worker injuries. But, an overhead crane can also be a dangerous piece of equipment if used…

Read MoreDaily Inspection for Workstation Bridge Cranes & Monorails

While only designated personnel may perform required maintenance and repairs on overhead crane systems, the crane operator should conduct inspections on a daily basis before and after use. A daily inspection checklist should be used and signed off on to ensure an effective and thorough assessment. OSHA 1910.179 refers to this daily inspection as a…

Read More