Safety Tips for Material Handling Cranes

May 30, 2023

Manufacturers and other industries use material handling cranes to lift and transfer heavy materials without putting unnecessary strain on workers. These cranes aid the production process and help workers avoid heavy lifting-related injuries.

As with all heavy machinery, crane operators must take precautions to keep material handling safer for everyone involved. Implementing the safety tips below can help create a safer workplace.

Checklist Before Moving a Load Safely

Implement the following crane safety measures before moving a load to ensure your worksite and coworkers are safer:

- Ensure crane operators are trained and qualified to operate the crane.

- Plan and lay out the job site, allowing space for emergency vehicles to pass if necessary and avoiding working near power lines.

- Follow a daily safety inspection sheet that includes a checklist before, during, and after each crane use.

- Verify the crane is equipped to hoist and transport the load.

- Assess ground conditions to determine if they’re stable enough to support the crane’s weight and load.

- Remove any loose parts, packing, and other materials from the load before lifting.

- Ensure the load is within the maximum rated capacity, which should be clearly and visibly marked on the crane.

- Ensure there’s no slack in the sling and hoist before raising the load.

- Ensure the aisles and space between equipment are wide enough and cleared of debris and unnecessary or dangerous parts.

- For a bridge crane, position the bridge directly over the load, and then place the trolley over the load before lifting. Make sure the sling sits in the hook’s center.

- Position yourself where you will have the best possible view of the load without putting yourself in potential pinch points.

- Notify workers in the material handling area that you will use an overhead crane to lift and transfer heavy materials.

How to Move Loads Safely

Once you’ve worked through the pre-moving safety checklist, use the following tips to move the load:

- Operate the controls carefully and deliberately, avoiding abrupt movements that could compromise the load. If the load starts swinging, it can damage nearby equipment and endanger nearby workers.

- Designate one person to call the lift, establish universal signals, and only follow their directions.

- Ensure all workers are out of the area before lifting. Ring an alarm and slowly begin raising the load.

- Ensure the crane’s hooks, slings, and hardware are suitable for the load and in sound condition, confirming all sling angles are appropriate.

- Ensure nothing can catch, attach to, or obstruct the load while lifting or transporting it.

- Raise the load a short distance at first to verify the brakes work before continuing the lift.

- For motorized systems, keep both hands on the pendant control. Releasing the control button — especially on accident — will cause the electric brake to set automatically.

- Remember that the pendant control for overhead bridge cranes moves the load in three directions: forward and backward, side to side, and up and down.

- Always lift the load straight up. Always raise it to the appropriate clearance height before transferring it.

- Lower the load with control. Set it on blocking, not the sling itself.

- Remain in the crane cab in the event of power failure. Switch the controls to the “off” position and wait for assistance.

Our Material Handling Overhead Crane Solutions

High-quality equipment is the best way to supplement your material handling safety efforts. Spanco offers thousands of pre-engineered overhead cranes, which can be customized to meet your specific application’s needs. We provide the following types of material handling cranes to cover a multitude of applications:

- Workstation Overhead Bridge Cranes

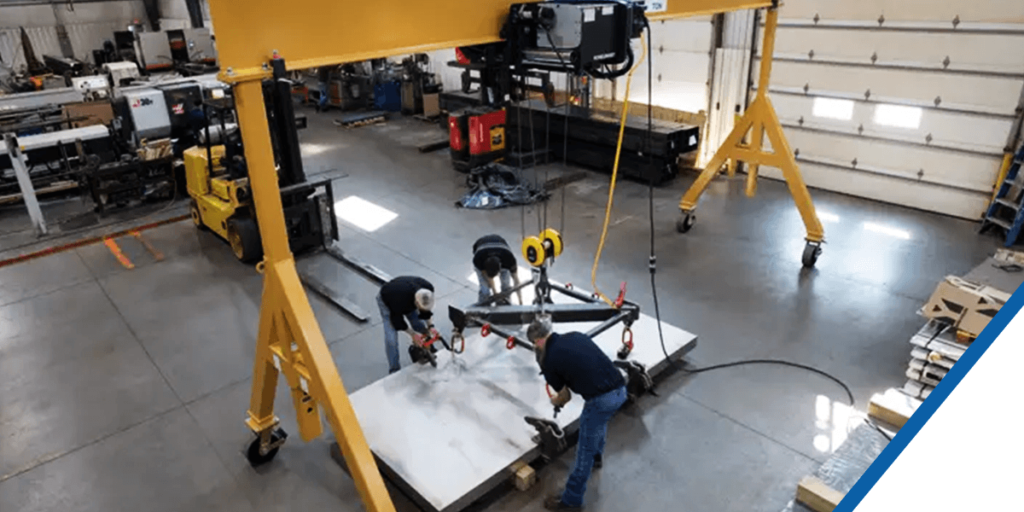

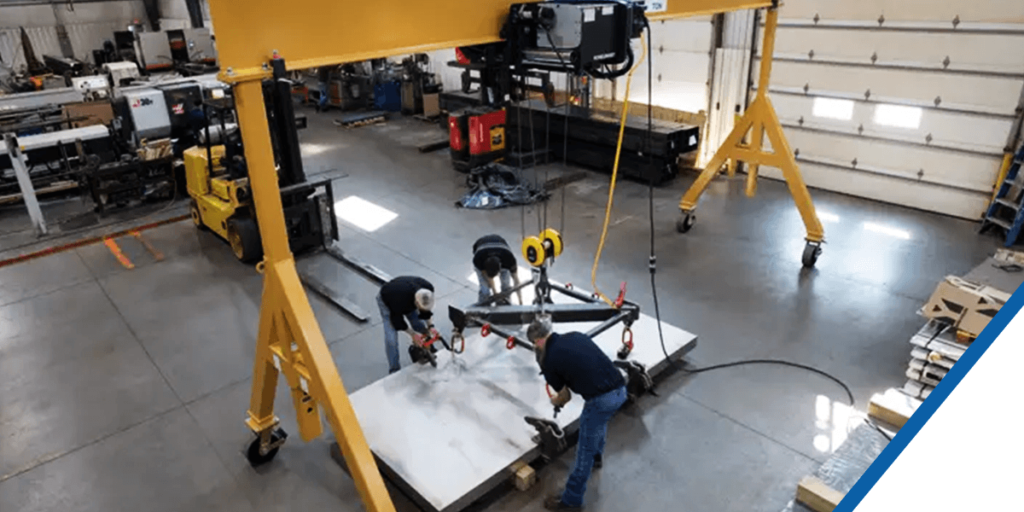

- Sturdy Mobile Gantry Cranes

- Articulating and Mast-Style Jib Cranes

- Monorail Material Handling Systems

- Industrial Tripods

Our material handling overhead crane systems use a movable hoist to raise and transfer heavy items laterally through an overhead space. They’re ideal for tasks such as:

- Moving equipment, tools, and supplies around the facility.

- Retrieving goods from storage.

- Loading and unloading materials from a transfer truck.

- Moving parts through an assembly line.

Spanco Is Your Trusted Source for Material Handling Systems

Here at Spanco, safety is a goal that we share with our customers. We want your job site to be safer and efficient, and that’s why you can rely on us for material handling solutions that manage your heavy loads, freeing up your employees to work on other tasks. Reach out to Spanco today to learn more about how our cranes can benefit your facility!

Categories

Share this post

Contact us

Looking for the perfect fall protection equipment? Let us help!