Protecting Slings Is the User’s Responsibility

Jan 10, 2022

Slings are a fundamental component of lifting and rigging operations. When lifting with a crane, slings are used to connect the load to the hoist hook or other lifting device. Depending on the way they are used and how they’re configured, slings can be used to stabilize oddly shaped objects, secure bundles of material, and support different types of loads.

The right sling, the appropriate type of hitch for a given load, and the number of slings required for a lift are important factors to know to be able to lift objects safely and protect slings from damage. When it comes to sling protection, it is crucial that users know all the best rigging practices, because they are the ones responsible for ensuring slings are used only if they are safe.

It’s intuitive that placing an unprotected sling under tension over a sharp edge is a bad idea. Even many laymen would say that a sling over a sharp edge probably requires protection to avoid damage. But sharp edges aren’t the only way a sling can become damaged. So, what are the best ways to ensure your slings are protected from all kinds of damage?

Know Your Slings

The first step to keeping your slings protected is to know what kind of slings you’re using and what kind of damage they might be susceptible to. There are a few different categories of slings; some of the most commonly used slings include synthetic web slings, wire rope slings, and alloy steel chain slings. Additional types include synthetic round slings, fiber rope slings, and metal mesh slings.

Synthetic web slings are popular because they are lightweight and flexible to form to the shape of a load. They are also less likely than other types to damage delicate loads or polished surfaces. Because they are made from synthetic fibers, such as nylon or polyester, these slings are susceptible to cuts or abrasions from rough or sharp objects. Exposure to high temperatures or acids can burn or melt the synthetic fibers, making them unusable.

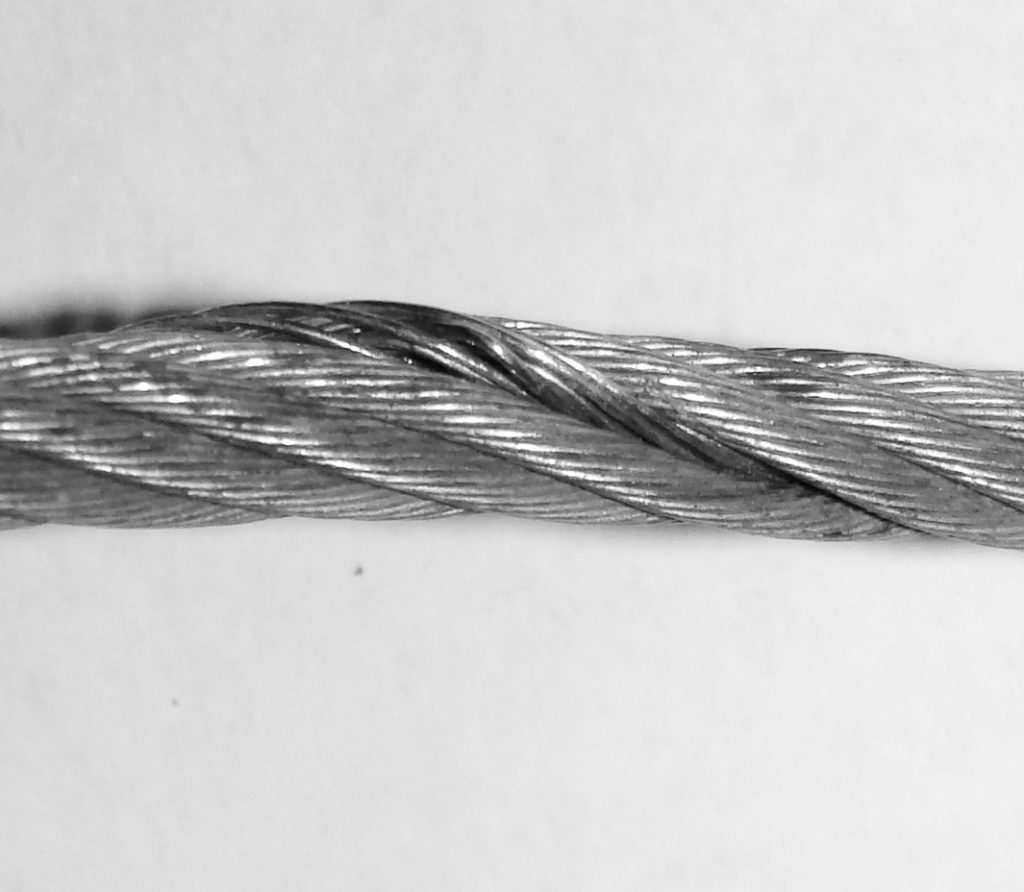

Wire rope slings are another common choice for rigging. Made from multiple strands of steel wire woven around a fiber or steel core, wire rope slings are strong, flexible, and able to endure higher temperatures than synthetic slings. Wire rope slings are much more resistant to cuts and abrasions than synthetic slings, but not entirely resistant. They are also susceptible to damage from kinking and cracking from small radius bends.

Steel alloy chains generally make the strongest and most durable slings. Chain slings are highly resistant to most kinds of damage, but sudden shocks or repeated impact can potentially weaken or break links. The greatest risk of damage to a chain sling in use come from impact to links that already have excessive wear, defective welds, nicks, cracks, or deformation. Fortunately, chains with damaged links can be repaired and recertified by the manufacturer.

Protective Measures

Once you know what kind of damage your slings are vulnerable to, you can take action to prevent damage from occurring. Synthetic slings can be protected from cuts and abrasions by using edge protection. Edges do not have to be razor-sharp to cut synthetic fibers. Any significant corner or edge can potentially damage a sling when the force of a load is applied, and the risk is increased if the sling shifts along the corner or edge of a load. To eliminate this risk, edge protection should be used to round out edges or corners. Various forms of padding can be used to soften edges, and many rigging supply companies provide engineered edge protection products.

Sharp corners and edges are also a risk condition for wire rope slings. While edges are less likely to cut or abrade wire rope than webbing, they can still cause damage. When the force of a load is applied to a wire rope sling that is bent at a sharp angle, wire strands can stretch and possibly break, causing the sling to kink and deform. Damage can also happen if a wire rope sling is used in a choker hitch at an angle that is too severe. Protect wire rope by ensuring it is never bent too sharply. When possible, use shackles or other rigging equipment to eliminate any looping or bending of a wire rope sling.

When it comes to chain slings, the highest risk of damage comes from sudden shock, as mentioned above. Chains can become twisted, causing the links to bunch together instead of aligning properly. If a chain is twisted when it is rigged, it can untwist under the load, causing sudden, severe impact. Ensure chain slings are never twisted to avoid shock damage when lifting.

If you want more information on sling safety, many organizations provide in-depth resources that can offer insight into proper use and protection of slings. The ASME B30.9 standard applies to the fabrication, attachment, use, inspection, and maintenance of slings used for load handling purposes. The Web Sling and Tie Down Association (WSTDA) provides industry information and best practices for different types of slings. Finally, OSHA’s Guidance on Safe Sling Use provides guidelines to help employers and employees avoid recognized hazards and ensure slings are used in compliance with labor laws.

Categories

Share this post

Contact us

Looking for the perfect fall protection equipment? Let us help!