Retrofit Drive Kits Provide Affordable Solution in the Manufacturing of Waste Management Equipment

Overview

Harris Waste Management Group is a Georgia based manufacturing company, which focuses on the design, production, and support of scrap processing, recycling, waste handling, and material reduction equipment. Harris Waste is a leading supplier of balers, shears, and shredders to the worldwide recycling industry.

“Just think of big car crushers, and that’s the type of thing we have to lift on a daily basis,” says Lonnie Leeman, Harris’ Director of Manufacturing. That’s exactly why they purchased Spanco Retrofit Drive Kits to upgrade existing manual freestanding jib cranes.

According to Leeman, Harris Waste Management uses jib cranes in its large parts inventories at both distributor sites and manufacturing plants to aid in the production process, which often includes lifting fuel plates up to 16 inches thick and moving steel welding joints in excess of 50 tons. Although they began purchasing and using cranes in 1992 to increase efficiency and safety in their production process, Leeman says that employees used to work outside with crawler cranes. Now, jib cranes have greatly improved the ergonomics of their working environment and their overall production process.

Solution

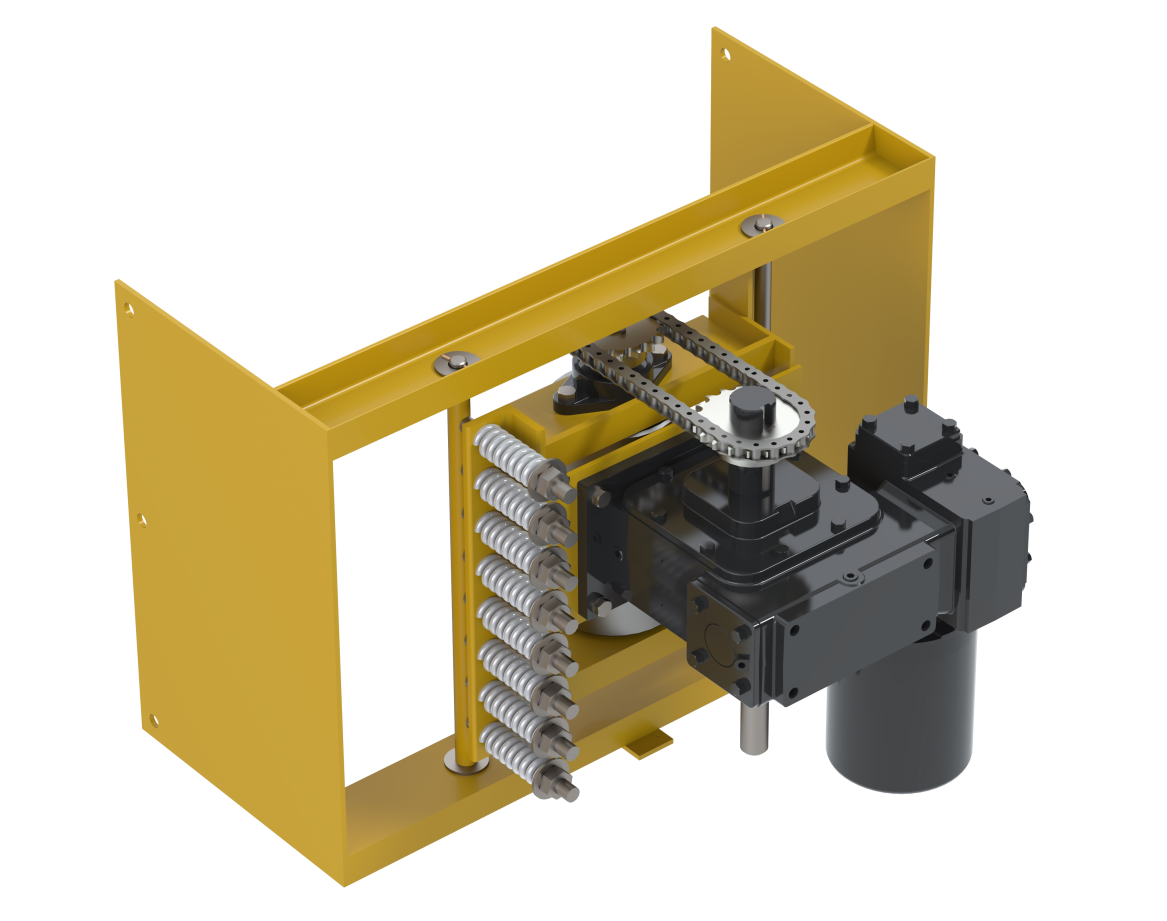

Spanco’s retrofit drive kits were an affordable solution to upgrade existing freestanding jib cranes from manual rotation to motorized rotation in each of the Harris Waste Management buildings. Due to their modular design, Spanco’s retrofit drive cranes fit their indoor freestanding jib crane applications with a box style head assembly by bolting to the back of the assembly. The retrofit drive power supply system consists of spring loaded dual poly tires, which run on the outer surface of the jib mast.

The high efficiency electric motor ensures good traction with large, worm gear reducer power steel rollers that contain polyurethane treads. The drive rollers provide a constant driving force with easy-to-adjust spring tension. Harris purchased a single speed control—although multi-speed controls are available—which use an IEC magnetic reversing starter, 120V control transformer, and three phase overload protection. All of this is prewired in a NEMA 3R indoor enclosure for optimal efficiency and safety.

Impact

As a world class leader in the manufacturing of ferrous processing equipment, Leeman recognizes the importance of installing and using a highly effective, safe, and affordable system that fits their indoor freestanding jib crane applications and helps to inspire an ergonomic work environment to support the production of their wide range of waste management equipment. Leeman says that Harris’ employees can operate the retrofit drive crane using a remote control, which considerably decreases the amount of time they spend operating the crane from a cab.

Spanco retrofit drive cranes are engineered for quality, durability, and reliability. If you have an application that requires a retrofit drive kit to upgrade an existing freestanding jib crane to powered rotation, Spanco has the experience and expertise to provide the perfect custom solution to meet your needs.