MOTORES DE MODERNIZACIÓN PARA GRÚAS BANDERA

Los motores de modernización para grúas bandera Spanco convierten su grúa bandera de rotación manual existente en una de rotación motorizada por una fracción del costo de una grúa motorizada nueva.

Estos equipos de conversión para grúas bandera son ideales para motorizar la rotación de cargas más pesadas o cuando la situación de su área de producción hace que la rotación manual del brazo sea insegura, poco práctica o improductiva.

| Modelo | Capacidad | Claro de la grúa bandera | Velocidad nominal |

| RDU-2 | 1.800 kg | 6 m (20′) | 1/2 RPM |

| RDU-3 | 2.700 kg (3 t) | 6 m (20′) | 1/2 RPM |

| RDU-5 | 4.500 kg (5 t) | 6 m (20′) | 1/2 RPM |

Opciones y componentes

Información Adicional

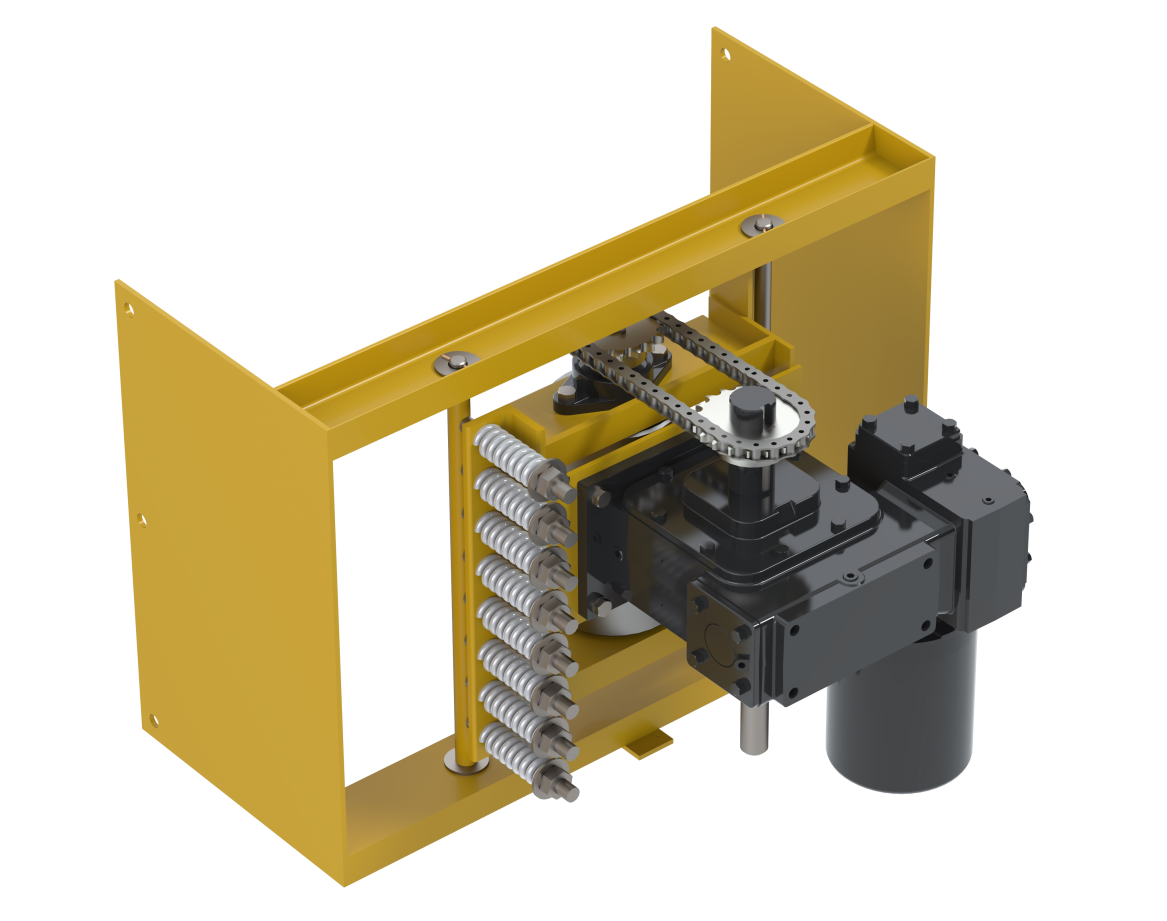

Los motores de modernización Spanco tienen un diseño modular que se emperna a la parte posterior de cualquier cabezal tipo caja.

Nuestro motor para grúa bandera cuenta con un motor eléctrico de alto nivel de eficiencia y reductor de tornillo sin fin ultra confiable.

El reductor de tornillo sin fin impulsa un conjunto de rodillos de acero de gran tamaño equipados con banda de rodamiento de poliuretano que le da una tracción y durabilidad excepcionales sobre el mástil de la grúa. Los rodillos se mantienen constantemente en la presión correcta contra el mástil mediante un mecanismo de ajuste de la tensión activado por resorte, asegurando una operación uniforme y sin problemas.

Tablero de control para grúas bandera: Incluye contactor de línea principal, contactores magnéticos de reversa, protección contra sobrecarga térmica, transformador de control de 110 V con fusible, fusible del circuito ramal al motor de la grúa y control de estado sólido (semiconductor) con capacidad de ajuste de tiempo y torque para un “arranque suave” —todo ello dentro de una caja eléctrica NEMA 3R.

Se recomienda el uso de motores de modernización Spanco únicamente para aplicaciones en interiores.

Spanco, Inc. warrants its products to be free from defects in material and workmanship as follows:

- Manual Systems & Equipment: Ten Years

- Motorized Systems & Equipment: One Year

- Paint & Finishes for Non-Aluminum Components: Two Years

Ten-Year Warranty Coverage:

- Defects in equipment material and workmanship of manual systems and equipment

- Wearable parts (workstation bridge crane end trucks and hoist trolley wheels only)

Spanco, Inc. warrants its manual workstation bridge crane, jib crane, and gantry crane products to be free from defects in material and workmanship for a period of ten (10) years or 20,000 hours, commencing on the date of shipment to the first retail purchaser. This warranty extends to non-wearable parts only, with the exception of the wheels supplied on manually operated workstation end trucks and hoist trolleys.

One-Year Warranty Coverage:

- Defects in equipment material and workmanship of motorized systems and equipment

Spanco, Inc. warrants motorized equipment to be free from defects in material and workmanship for a period of one (1) year or 2,000 hours, commencing on the date of shipment to the first retail purchaser.

Two-Year Warranty Coverage:

- Paint coatings and finishes for non-aluminum components

Spanco, Inc. warrants its paint and finishes for a period of two (2) years. Warranty claims related to coatings must be accompanied by documentation of the product’s application and environmental conditions from time of delivery to time of claim.

WARRANTY TERMS & CONDITIONS

All warranty claims must be approved by Spanco before any work is performed. Spanco’s obligation under this warranty is limited to the replacement or repair of Spanco products at the factory or separate location approved by Spanco. Other than the above mentioned warranty, Spanco will not honor any other warranties—whether expressed, implied, or statutory—and disclaims any warranties of merchantability or fitness for a particular purpose. Spanco has the right to reject any warranty claim due to harsh and/or inappropriate environmental conditions.

Spanco Is Not Liable for:

- Indirect, incidental, or consequential damages including lost profits, operating costs, loss of production, or travel expenses

- Components or accessories not manufactured by Spanco

- Defective equipment or system failure caused by misuse, negligence, and improper installation or maintenance

- Equipment that has been used in excess of its rated capacity or beyond its service factors

- Equipment that has been altered without Spanco’s written authorization

- Damage incurred by freight carriers

- Any loss, injury, or damage to persons or property resulting from failure or defective operation of material or equipment

Reimbursement Disclaimer:

- Written notice of any claimed system defect must be given to Spanco within ninety (90) days of shipment.

- All requests for reimbursement must be accompanied by proper documentation.

- Reimbursement is provided in the form of a credit unless otherwise approved by Spanco management.

- Reimbursement for labor will be provided at a maximum rate of $75 per hour.

- All reimbursement is subject to approval by Spanco management.

General Design Standards:

Spanco cranes are designed in conformance with the following applicable standards:

- Workstation Bridge Cranes: AISC Steel Construction Manual, OSHA 1910.179, ANSI B30.11, AWS D1.1/D1.6, and MMA MH27.2

- Gantry Cranes: AISC Steel Construction Manual, OSHA 1910.179, ANSI B30.11, AWS D1.1/D1.2/D1.6, and CMAA 74

- Jib Cranes: AISC Steel Construction Manual, OSHA 1910.179, ANSI B30.11, AWS D1.1/D1.6, and CMAA 74

All Spanco cranes have a design factor of 15% of the allowable capacity for the weight of the hoist and 25% for impact.

Fabrication Standards:

All welding performed during the manufacturing of Spanco cranes meets the following American Welding Society’s (AWS) standards: D1.2 for aluminum and D1.1 for steel.

Spanco is officially certified as an AWS Certified Welding Fabricator (CWF). This certification means that not only are all welders AWS Certified, but all processes and procedures adhere to AWS CWF requirements. Examples of requirements include annual calibration of all welding machines and Level 2 visual inspections on all load-bearing components.

Material Standards:

All aluminum used in the manufacturing of Spanco cranes meet ASTM International specification ASTM B308 for 6061-T6 aluminum.

All steel used in the manufacturing of Spanco cranes meets the following applicable ASTM International specifications:

Structural Steel Shapes: ASTM A-36

Structural Steel Pipes: ASTM A-53 Grade B

Structural Square and Rectangular Steel Tubing: ASTM A-500 Grade B

Steel plate and round bar used in Spanco cranes have minimum yield strengths of 36 KSI

Surface Preparation & Painting Procedures:

Spanco adheres to the standards of the Society for Protective Coatings (SSPC) for all product surface preparation. Prior to painting, all Spanco crane components are deburred and descaled using power tools equipped with sanding discs and wire wheels. Components are then washed utilizing a high-pressure/high-temperature biodegradable degreaser solution. Parts are wiped clean and allowed to dry before the painting process. During painting, all components surfaces are coated with a quick drying, semi-gloss enamel, applied to a minimum dry-film thickness of 2 to 3 mils. A finishing coat is applied with a hot, airless, electrostatic spray paint system. Painted components are cured at air temperature.

Deflection Guidelines:

The following guidelines for deflection and stress are followed by Spanco engineers during the crane design process:

- Workstation Bridge Cranes: All models are designed to approximately L/450

- Jib Cranes: Freestanding (100, 101, and 102 Series), Mast Style (200 and 201 Series), Wall-Mounted Cantilever (300 Series), Articulating (400, 401, and 402 Series), and Foundationless models (600 and 605 Series) are designed to approximately L/150; Wall-Mounted Bracket (301 Series) models are designed to approximately L/600 at midspan

- Workstation Jib Cranes: Wall-Mounted (WC Series) models are designed to approximately L/225; Freestanding (FR Series) models are designed to approximately L/150

- Gantry Cranes: All steel series models are designed to approximately L/600; Aluminum models are designed to approximately L/450

Quality Standards:

Spanco is an ISO 9001-2008 Registered corporation. This means that Spanco cranes are manufactured to standards ensuring safety, reliability, and the highest quality. Spanco’s ISO designation also allows for continuous improvement based on customer feedback.

- Inspeccione todo el sistema una vez al año o con más frecuencia según lo define la norma OSHA 1910.179. La inspección debe estar a cargo de una persona calificada. No hacerlo así puede ocasionar lesiones serias o causar la muerte.

- Nunca intente ajustar las funciones eléctricas de este sistema o trabajar en ellas a menos que sea usted electricista industrial certificado.

- Cualquier trabajo con o ajuste de las funciones eléctricas de este sistema por cualquier persona que no sea electricista industrial certificado anulará la garantía.

- Nunca utilice la grúa como conductor de puesta a tierra. Se requiere contar con cable y trayecto independiente a tierra para todas las instalaciones eléctricas.

- Lea y entienda el Manual de Operación antes de operar este equipo.

- Se debe seguir los procedimientos de bloqueo y etiquetado de la OSHA antes de realizar cualquier ajuste o mantenimiento en este equipo.

- Nunca transporte personas.

- Nunca opere este sistema si todos los dispositivos de protección no están en su lugar.

- Nunca modifique el sistema del motor o los componentes del sistema sin el consentimiento expreso de Spanco.

- La modificación de este sistema anulará la garantía.

- Nunca opere un motor sin los topes de extremo instalados en las pistas.

- Nunca opere un motor con carga lateral.

- Todo ruido inusual u operación inusual del motor debe ser identificado y corregido de inmediato.