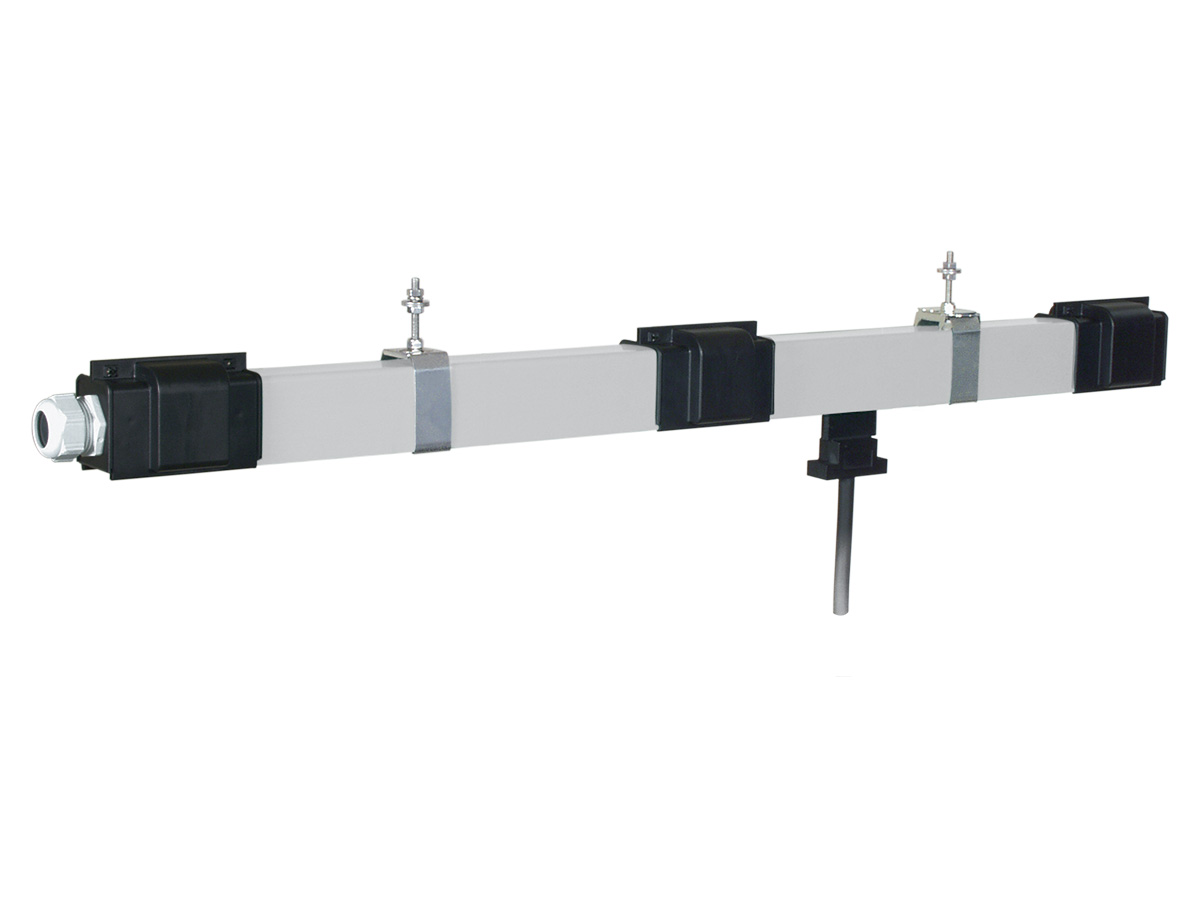

Enclosed Conductor Bar Systems

Spanco offers enclosed conductor bars for use with manual and motorized workstations, delivering an ergonomic electrical collecting system. The lightweight, compact design is ideal for installation in tight, hard to reach areas. This easy to maintain system includes a standard double collector for use with variable frequency drives.

Options & Components

Additional Information

FEATURES & BENEFITS

- Enclosed design of touch-safe housing increases operational safety while protecting the system from environmental implications.

- Modular components provide smooth and easy installation and decreased maintenance, reducing overall system costs.

- Lower collector friction provides smoother movement of enclosed track workstations.

- Maintenance and drop out sections are available for quick and easy collector removal.

- System can be readily retrofitted to existing Spanco workstation cranes.

PtP Spanco, Inc. warrants its products to be free from defects in material and workmanship as follows:

- Manual Systems & Equipment: Ten Years

- Radio Controlled Transmitters and Receivers: Two Years

- Motorized Systems & Equipment: Two Years

- Enclosed Conductor Bar Systems: 1 Year

- Paint & Finishes for Non-Aluminum Components: Two Years

Ten-Year Warranty Coverage:

- Defects in equipment material and workmanship of manual systems and equipment

- Wearable parts (workstation bridge crane end trucks and hoist trolley wheels only)

PtP Spanco, Inc. warrants its manual workstation bridge crane, jib crane, and gantry crane products to be free from defects in material and workmanship for a period of ten (10) years or 20,000 hours, commencing on the date of shipment to the first retail purchaser. This warranty extends to non-wearable parts only, with the exception of the wheels supplied on manually operated workstation end trucks and hoist trolleys.

One-Year Warranty Coverage:

- Defects in equipment material and workmanship of motorized systems and equipment

PtP Spanco, Inc. warrants motorized equipment to be free from defects in material and workmanship for a period of one (1) year or 2,000 hours, commencing on the date of shipment to the first retail purchaser.

Two-Year Warranty Coverage:

- Paint coatings and finishes for non-aluminum components

PtP Spanco, Inc. warrants its paint and finishes for a period of two (2) years. Warranty claims related to coatings must be accompanied by documentation of the product’s application and environmental conditions from time of delivery to time of claim.

WARRANTY TERMS & CONDITIONS

All warranty claims must be approved by PtP Spanco, Inc. before any work is performed. PtP Spanco’s obligation under this warranty is limited to the replacement or repair of PtP Spanco, Inc. products at the factory or separate location approved by PtP Spanco, Inc.. Other than the above mentioned warranty, PtP Spanco, Inc. will not honor any other warranties—whether expressed, implied, or statutory—and disclaims any warranties of merchantability or fitness for a particular purpose. PtP Spanco, Inc. has the right to reject any warranty claim due to harsh and/or inappropriate environmental conditions.

PtP Spanco, Inc. Is Not Liable for:

- Indirect, incidental, or consequential damages including lost profits, operating costs, loss of production, or travel expenses

- Components or accessories not manufactured by PtP Spanco, Inc.

- Defective equipment or system failure caused by misuse, negligence, and improper installation or maintenance

- Equipment that has been used in excess of its rated capacity or beyond its service factors

- Equipment that has been altered without PtP Spanco’s written authorization

- Damage incurred by freight carriers

- Any loss, injury, or damage to persons or property resulting from failure or defective operation of material or equipment

Reimbursement Disclaimer:

- Written notice of any claimed system defect must be given to PtP Spanco, Inc. within ninety (90) days of shipment.

- All requests for reimbursement must be accompanied by proper documentation.

- Reimbursement is provided in the form of a credit unless otherwise approved by PtP Spanco, Inc. management.

- Reimbursement for labor will be provided at a maximum rate of $90 per hour.

- All reimbursement is subject to approval by PtP Spanco, Inc. management.

General Design Standards:

Spanco cranes are designed in conformance with the following applicable standards:

- Workstation Bridge Cranes: AISC Steel Construction Manual, OSHA 1910.179, ANSI B30.11, AWS D1.1/D1.6, and MMA MH27.2

- Gantry Cranes: AISC Steel Construction Manual, OSHA 1910.179, ANSI B30.11, AWS D1.1/D1.2/D1.6, and CMAA 74

- Jib Cranes: AISC Steel Construction Manual, OSHA 1910.179, ANSI B30.11, AWS D1.1/D1.6, and CMAA 74

All Spanco cranes have a design factor of 15% of the allowable capacity for the weight of the hoist and 25% for impact.

Fabrication Standards:

All welding performed during the manufacturing of Spanco cranes meets the following American Welding Society’s (AWS) standards: D1.2 for aluminum and D1.1 for steel.

Spanco is officially certified as an AWS Certified Welding Fabricator (CWF). This certification means that not only are all welders AWS Certified, but all processes and procedures adhere to AWS CWF requirements. Examples of requirements include annual calibration of all welding machines and Level 2 visual inspections on all load-bearing components.

Material Standards:

All aluminum used in the manufacturing of Spanco cranes meet ASTM International specification ASTM B308 for 6061-T6 aluminum.

All steel used in the manufacturing of Spanco cranes meets the following applicable ASTM International specifications:

Structural Steel Shapes: ASTM A-36

Structural Steel Pipes: ASTM A-53 Grade B

Structural Square and Rectangular Steel Tubing: ASTM A-500 Grade B

Steel plate and round bar used in Spanco cranes have minimum yield strengths of 36 KSI

Surface Preparation & Painting Procedures:

Spanco adheres to the standards of the Society for Protective Coatings (SSPC) for all product surface preparation. Prior to painting, all Spanco crane components are deburred and descaled using power tools equipped with sanding discs and wire wheels. Components are then washed utilizing a high-pressure/high-temperature biodegradable degreaser solution. Parts are wiped clean and allowed to dry before the painting process. During painting, all components surfaces are coated with a quick drying, semi-gloss enamel, applied to a minimum dry-film thickness of 2 to 3 mils. A finishing coat is applied with a hot, airless, electrostatic spray paint system. Painted components are cured at air temperature.

Deflection Guidelines:

The following guidelines for deflection and stress are followed by Spanco engineers during the crane design process:

- Workstation Bridge Cranes: All models are designed to approximately L/450

- Jib Cranes: Freestanding (100, 101, and 102 Series), Mast Style (200 and 201 Series), Wall-Mounted Cantilever (300 Series), Articulating (400, 401, and 402 Series), and Foundationless models (600 and 605 Series) are designed to approximately L/150; Wall-Mounted Bracket (301 Series) models are designed to approximately L/600 at midspan

- Workstation Jib Cranes: Wall-Mounted (WC Series) models are designed to approximately L/225; Freestanding (FR Series) models are designed to approximately L/150

- Gantry Cranes: All steel series models are designed to approximately L/600; Aluminum models are designed to approximately L/450

Quality Standards:

Spanco is an ISO 9001:2015 Registered corporation. This means that Spanco cranes are manufactured to standards ensuring safety, reliability, and the highest quality. Spanco’s ISO designation also allows for continuous improvement based on customer feedback.

- Inspect entire system annually or more frequently as defined by OSHA 1910.179. Inspection must be performed by a qualified person. Failure to do so may cause serious injury or death.

- Never attempt to work on or adjust the electrical functions of this system unless you are a certified industrial electrician.

- Working on or adjusting the electrical functions of this system by anyone other than a certified industrial electrician will void the warranty.

- Never use a crane as electrical ground. A separate ground wire and ground path is required for all electrical installations.

- Read and understand the Operation Manual before operating this equipment.

- OSHA Lock-out Tag-out procedures must be followed before performing any adjustments or maintenance on this equipment.

- Never transport humans with any power drive.

- Never operate this system without all safety guards in place.

- Never modify power drive system or system components without express written consent from Spanco.

- Unauthorized modification of this system will void the warranty.

- Never operate a power drive without end stops installed on tracks.

- Never side load a power drive.

- All unusual noises and unusual drive operations must be immediately identified and corrected.